Ductile Iron Casting Fittings

Complete range of ductile iron fittings and special developments

Complete range of ductile iron fittings and special developments. Different joining systems are available: Plug with TYTON® Gasket, Flanges and Restrained Joint.

Characteristics and Joining Systems

Characteristics

- Available for Drinking Water (EN 545 / ISO 2531) and Wastewater (EN 598)

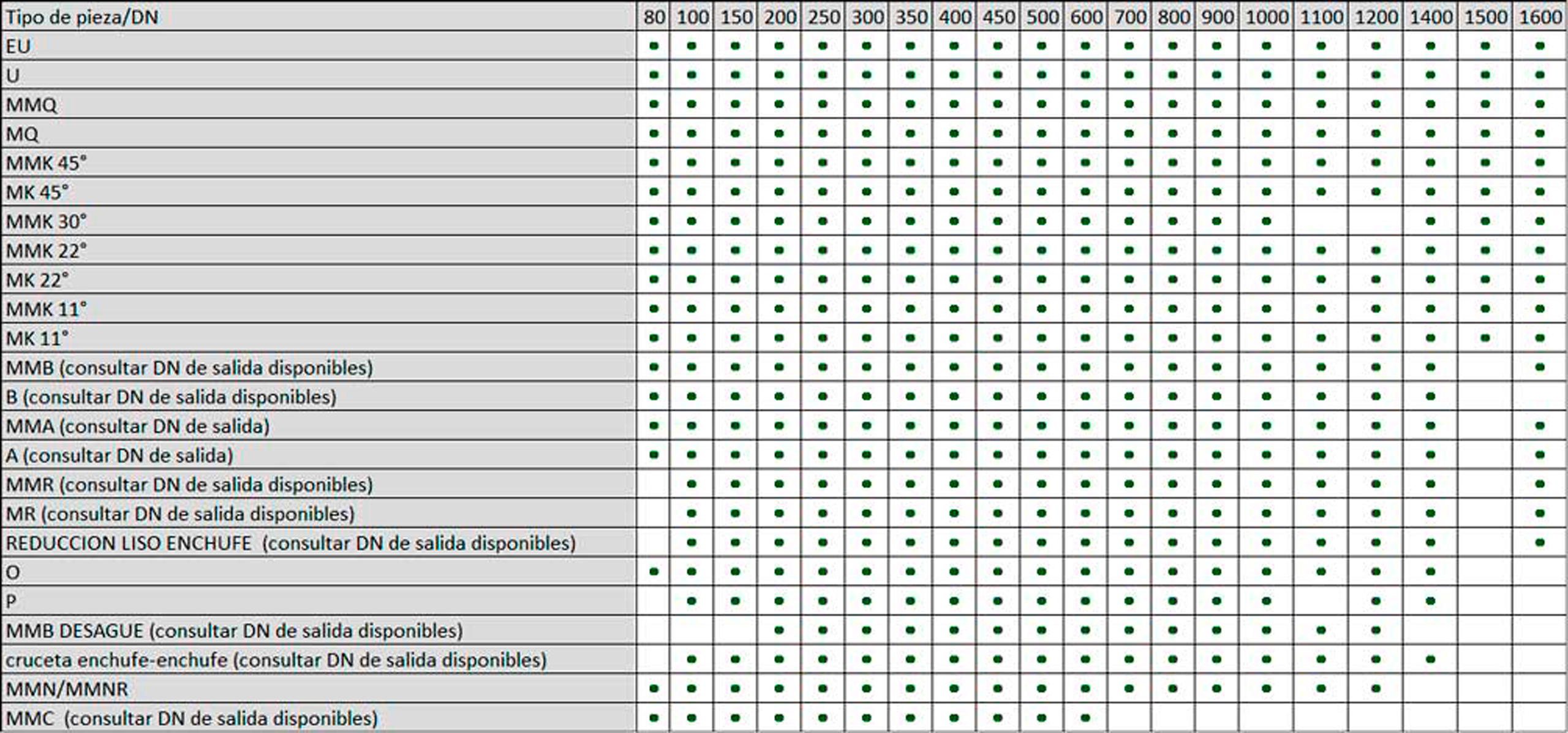

- Full range between ND 80 and ND 2600

- K12 / K14 wall thickness

- Pressure Rate: Consult depending on the type of joint, up to RWP of 100 bar depending on joining system.

- Lining and Coatings: Internal cement and external bitumen. Internal and External epoxy with a minimum thickness of 250µ according to EN 14901. Consult for other coatings.

Joining Systems

- TYTON® Gasket Fittings: ND 80 to ND 2600

- Flanged Fittings: ND 80 to ND 2000

- Lok & Play® Double chamber restrained fittings DC LOK: from ND 80 to ND 1600

TYTON® Gasket Fittings / Flanged Fittings

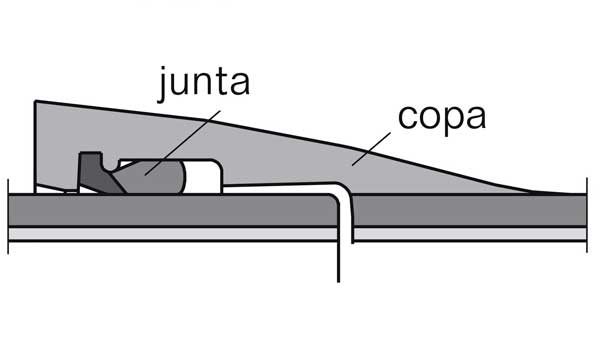

The tightness of the TYTON® Gasket is generated by means of deformation caused by the water pressure. The TYTON® Gasket, generally in EPDM or NBR, is located inside the socket of the element where the spigot of the adjacent element is inserted. It is in between the socket and the spigot. The back side of the TYTON® Gasket is the softer side. Tightness is based on the principle of “the greater the pressure, the greater the sealing”.

The flange gasket generates watertightness by deformation of a flat gasket located between the flat surfaces of two flanges that is tightened by screws.

| TYTON Socket Joint | Flanged Joint |

|---|---|

| RWP 40 up to ND 600 | NP 10/16/25/40 up to ND 600 |

| RWP 25 up to ND 2600 | NP 10/16/25 up to ND 2000 |

| Description | Code | Icon | Downloading link |

|---|---|---|---|

| Double Socket 11.25º Bend | MMK11 | Download | |

| Double Socket 22.50° Bend | MMK22 | Download | |

| Double Socket 30º Bend | MMK30 | ||

| Double Socket 45º Bend | MMK45 | Download | |

| Double Socket 90º Bend | MMQ | Download | |

| Single Socket 11.25° Bend | MK11 | ||

| Single Socket 22.50º Bend | MK22 | Download | |

| Single Socket 30º Bend | MK30 | ||

| Single Socket 45º Bend | MK45 | ||

| Sleeve | U | ||

| All Socket Tee | MMB | ||

| Double Socket with 45º branch | MMC | ||

| Double Socket Taper | MMR | ||

| Spigot Plug | O | ||

| Socket Cap | P | ||

| Screwed Ring for P Part | P | ||

| Screwed Cap for Screwed Socket | PX | ||

| Home supply connection with 2" internal screwed outlet | HAS | ||

| ENQ Part | ENQ | ||

| 90º Bend with skid for snow cannon | ENH | ||

| Smoothed end Pipe Section | GL | ||

| Flanged Socket | EU | Download | |

| Socket and Flanged 90º Bend with skid | EN | ||

| Double Socket Tee with Flanged Branch | MMA | ||

| Double Flanged 11.25º Bend | FFK1 | ||

| Double Flanged 22.50º Bend | FFK22 | ||

| Double Flanged 30º Bend | FFK30 | ||

| Double Flanged 45º Bend | FFK45 | Download | |

| Double Flanged 90º Bend | Q | Download | |

| Flanged Smooth Pipe | F | ||

| Triple Flanged Tee | T | Download | |

| Flanged Cross | TT | ||

| Flanged Concentric Reducer | FFR | Download | |

| Flanged Eccentric Reducer | FFRe | ||

| Double Flanged 90° Bend with Skid | N | ||

| Blind Flanges | X |

Lok&Play Locked Accessories

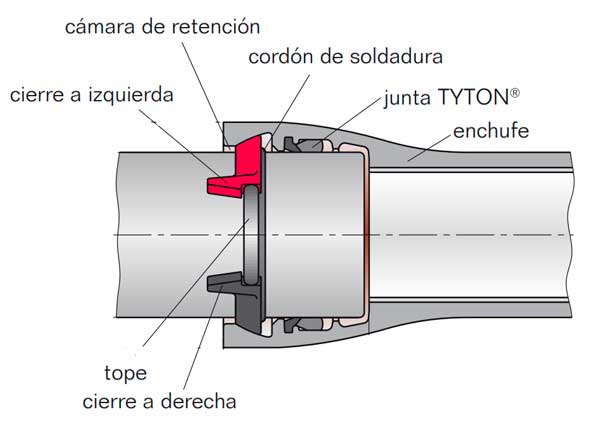

The socket has two chambers, the first one lodges the Tyton® gasket, which makes the joint watertight. The second chamber has a window (or several, depending on the diameter) over which the locking segments are inserted once the end of the tube is plugged in; these provide a positive axial seal between the inside surface of the socket and the locking cord at the smooth end of the pipe.

| Pressure | High Pressure |

|---|---|

| RWP 40 bar from ND 80 to ND 300 | RWP 100 bar from ND 80 to ND 300 |

| RWP 30 bar from ND 350 to ND 600 | RWP 64 bar ND 400 |

| RWP 25 bar from ND 700 to ND 1000 | RWP 50 bar ND 500 |

| RWP 40 bar ND 600 |

Available stock range